Challenges in Integrating Modern Technologies with People

Integrating Technologies and

Human Resources -– the biggest challenge for Supply Chain Companies

Integrating Technologies and

Human Resources -– the biggest challenge for Supply Chain Companies

By:

In modern trade regime, strong interdependence between various

activities of supply chain management and logistics management is witnessed. It

is thus difficult to identify precise boundaries. In other words there is a tendency

to oversimplify the supply chain issues or to make it too complicated by adding

too many issues, which are not required for efficient business operations.

In modern supply chain, these boundaries are continuously

moving to accommodate an integration of supply chain and logistics activities

depending upon the changing consumer expectations. In fact, it is suggested

that logistics is a sub-function of the supply chain. While logistics may be

involved to some extent in an increasing number of supply chain activities but

it can never be a part of the complete supply chain spectrum.

In practice, functions such as sourcing, manufacturing,

customer service and retailing involve logistics in their planning and

scheduling for optimizing the end-to-end supply chain, but their core

operations are somewhat different.

The Council of Supply Chain Management Professionals says

that “Supply Chain Management encompasses the planning and management of all

activities involved in sourcing and procurement, conversion, and all Logistics

Management activities. Importantly, it also includes coordination and

collaboration with channel partners, which can be suppliers, intermediaries,

third-party service providers, and customers.”

Supply Chain Management in order to be more effective should

integrate supply and demand management within and across companies. It is thus

integrating function is the primary responsibility of the head of business to ensure

effective linkages of major business functions and business processes within

and across companies into a cohesive and high performing business model.

It includes all of the logistics management activities as

well as manufacturing operations, and it drives coordination of processes and

activities within and across marketing, sales, product design, and finance

& information technology functions.

An increasingly important component to the supply chain

sector is the emergence of functional and process outsourcing, thus creating

the need for businesses (i.e. third party logistics providers, i.e. 3PLs) that

are specialized in providing complete set of logistics services. As a result, now

there is a well defined role for logistics/supply chain users and

logistics/supply chain service providers.

It is observed that the most common supply chain activities

completed in-house focus on inventory management and customer service,

including processing and executing orders. Conversely, the most common

outsourced activities focus on transportation of goods (i.e., outbound and

inbound transportation, and freight forwarding), customs (i.e., brokerage and

clearance) and, to a lesser degree, warehousing. In modern world many new

functions and dimensions can be added to the outsourcing basket to keep organization

lean.

According to the market estimates, the growth rate for this

market is about 20%, with the annual growth rate for warehousing, transportation

management, air/ocean freight forwarding, and dedicated carriage (four core

logistics sections) being 15% to 25%.

From a geographic perspective, the supply chain-oriented

organizations typically operate in multiple regions across the country and

internationally. Only a few operate in one region alone. Most of the regional

players have their specific territories to operate and they offer more than

just logistics support.

Internationally, the modern supply chain evolved in U.S.,

followed by Europe and Asia Pacific. In most companies the supply chain

function is generally centralized and headed by a senior manager.

Not only has the supply chain function evolved from strictly

storage and transportation to an active integration with many other supply

chain activities, but it is also shifting in terms of perception from being a

common cost centre to playing a strategic competitive role. The nature of work

in this sector is changing as the supply chain becomes more complicated and

strategic, and organizations try to manage the full supply chain, rather than

its individual parts.

Trends in Human Resource Management in Supply Chain:

In an increasingly integrated international market, issues

like global security, international trade, international competition and

border-crossing requirements are all affecting the supply chain sector, and are

expected to continue to do so over the next five to ten years. At the same time the supply chain management is facing increasing

complexity, financial/cost pressures, and increasing speed and quality

expectations.

Customers and competitors are exerting enormous pressure on

supply chain logistics. More specifically, the linkages between supplier

effectiveness, supply chain performance, and customer service have become

critical.

Challenge for

Supply Chain mangers:

Having improved manufacturing efficiency and product quality

in the past, suppliers now need to improve their collaboration with retailers

and customers in order to respect their delivery requirements. Increasing

customer expectations/demands, in terms of speed and quality, place an

increased focus on customer service.

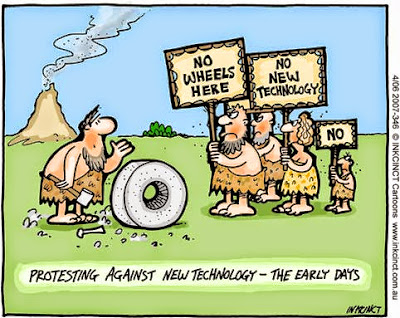

The biggest challenge in technology adoption is mindset of decision

makers and managers and their attitude towards acting like power centers within

the organization and now willing to adopt a system which can require minimum

human interventions. Many decision makers

and managers are not willing to delegate their decision-making powers to

system-oriented approach.

In general, most of the organizations lag in both investment

and implementation of new technologies. While information management and

technology is one of the most common activities reported as falling under the

responsibility of the supply chain function, but this technology appears to be

under-utilized. The degree of technology use reported by much organization is

very often exaggerated or not utilized to their full potential. As a result the

use of ERPs is limited and stand-alone systems for specific functions are

common.

Adoption of Technology

is the key business driver:

Technology is clearly an important tool in any company's

efforts to respond to ever-increasing customers' expectations. Small and

medium-sized organizations cannot often afford the latest technologies required

to remain competitive in their respective markets. This is also one of the

reasons for growing acquisition and mergers in the supply chain sector.

Consequently, there has been a widespread increase in the number of third-party

service providers, as well as their reliance on contemporary information system

services.

Technology and the resulting information management

requirements are identified as key business drivers currently impacting the

supply chain function.

Successful Technology adoption will decide the existence:

Information management systems and related technology have

evolved at a more rapid pace and have had a more profound impact on job design

and skill requirements than process and production technology. Unfortunately, most

of the organizations are not prepared for the level of technological

integration that is required to compete successfully.

Technology is most commonly employed for inventory and

warehousing management. Looking forward decision makers should consider employing

technology for transportation. These technologies can also be used to manage customer

and supplier relationship management. Not surprisingly, larger organizations

have implemented more supply chain-related information systems than smaller

ones.

Unskilled

manpower hurts technology adoption process:

Interestingly, despite the number of organizations that

indicate that technology is applied in their organization, few indicate that

they currently have the requisite skills to fully employ technology.

Organizations want to continuously update their technology

to improve efficiency, but their ability to keep pace with technological change

is a challenge. The introduction of technology is changing the nature of work

for all occupational categories (i.e., managerial as well as operational

manpower). They are changing in terms of increased pace of work with less lead

time and more real-time information. The growing information needs also demands

increased requirement to manage this influx of diversified information.

As a result of technological change, software application

and analytical and decision-making skills are rapidly replacing traditional

manual processes and abilities. It appears that many employees have been able

to adapt to this evolution, other needs encouragement to do so.

There are divergent views with respect to whether existing employees

possess technically adaptable skills or not. Decision makers often say that

their employees do not have the requisite technical skills but employees on the

other hand indicate that they are not provided with adequate training to make

full use of technology.

Unfortunately academic institutions and training organizations

do not have technically competent staff for teaching with practical exposure in

the areas where employers employ technology.

In the short term, Employers are dealing with these skill

gaps by focusing on in-house and on-the-job training. In the longer term, it is

essential to have collaborative effort for technical skill development by

creating industry and academic institution alliances.

Going forward in market place, as a result of technology

introduction, it is anticipated that there will be further emphasis on the

importance of instantaneous adaptation to customer requirements, information

management and general management skills. If competitors are offering instant service,

can you afford to adopt a system which is not responsive to customer needs?

Missing link is effective trainers with diversified

practical knowledge:

Based on my interaction with many supply chain managers in

many companies and after studying their supply chain systems and people

involved in the system, it is clear that the training components are either ill

conceived or improperly executed.

One of the reasons given is that most of their trainers have

no experience of operating issues in supply chain management and how to make

technology adoption user friendly. Many experts make things complicated in

place of making them simple for adoption.

Most of the trainers, due to their own ignorance of working

environment, either discuss concepts or features of technology but very rarely

understand or explain the human side of business of supply chain, practical

issues and their integration with technology. Many trainers don’t prefer to customize

their training programs due to lack of their own understanding of the new

environment.

In author's view, effective training is vital for smoother

adoption of technology under given constraints. In modern world, it is the responsibility

of the trainer to motivate trainees to adopt new skills and environment.

Comments

Post a Comment